Warehouse Slotting

Trommer & Associates, Inc. uses the latest economic based slotting software to optimize inventory placement inside your warehouse and reduce day-to-day operating expenses. This technology is just one of many tools Trommer & Associates uses to provide our clients with exceptional service.

Slotting Overview

Slotting refers to the placement of your inventory in your facility. Properly done, slotting ensures each item is stocked in the best place in your warehouse to save space and make picking easier. Proper placement of each item in your system can increase picking efficiency, improve cube utilization and reduce your company’s total operating costs.

Traditional slotting programs look only at the cube and velocity of an item to determine where to place it. While this method often results in adequate results as far as the picking process is concerned, it may not be the most efficient scenario, meaning you could still reduce costs. An “economic based slotting program” takes into account factors such as inventory levels, replenishment costs, storage costs and product placement (ergonomics). This more complex algorithm delivers more refined solution resulting in the lowest possible operating cost.

A proper economic based slotting program is computer generated using slotting software that incorporates known project data as well as intimate knowledge of your business. Computerized slotting allows Trommer & Associates, Inc. to significantly improve your facility’s cost / efficiency ratios.

Slotting Benefits

The benefits of economic based slotting for your inventory are many, and include the following:

- Slotting an existing layout establishes a baseline for cost and effectiveness, which can then be used to evaluate the effectiveness of different slotting alternatives.

- Slotting can be used to determine the size of a facility, to validate the storage media type, and to determine the best level of quantity which can be stored in the facility.

- Slotting can be used to forecast operating costs for different levels of business.

- Slotting can be used to answer questions about a proposed layout change, allowing us to predict the potential benefits of a new layout prior to your making a large capital investment.

- Slotting provides an optimal shelving configuration layout, unlike other slotting methods which require you to select a shelving configuration through "trial and error".

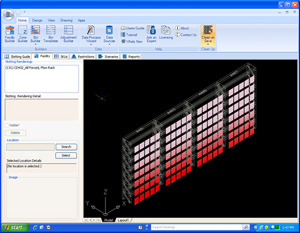

- Slotting software can provide a viewable representation of a proposed system. Instead of looking at a computer listing, you can actually see the anticipated activity. This not only provides an understanding of how a layout will work, it provides visual cues to potential problems (such as bottlenecks) which can then be addressed prior to implementation.

- Slotting can quickly analyze data for a number of alternative layouts and steer you towards the solution that best minimizes your operating costs. This lets you get back to the job of managing your warehouse, instead of being stuck in front of a computer juggling spreadsheets.

These and many other benefits can be provided by our economic based slotting solution package. All distributions systems can benefit from some level of slotting, but the best solution is one that reduces your operating cost at all levels. Trommer & Associates, Inc, is dedicated in providing the best possible solution in every situation.